Induction preheater for extrusion coating lines of electrical cables

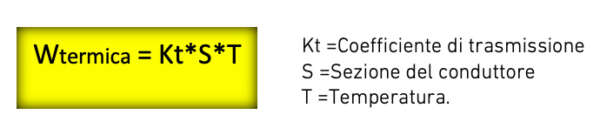

Among the various technological steps involved in the production of electrical cables, the heat treatment of the metal wires that make them up, such as copper, aluminium, etc., takes on considerable importance, which, during the drawing process, changes the physical properties of conductivity, corrosion resistance and reduced ductility.

The work hardening of the conductor also reduces its valuable flexibility in use, hence the imperative need for heat treatment to restore its crystalline structure.

INTECH Automazione Sistemi s.r.l. has considerable experience in the construction and automation of switchboards for copper and aluminium wire drawing plants, roughing machines, intermediate drawing machines and capillary drawing machines, with associated continuous annealing controls.

The company has been active for years in producing electrical cables with the realisation of complex systems for single and triple extrusion coating lines (polymers, fluorinated, fibres).

Because of the frequent need to introduce in-line, before the extruder, low-temperature heat treatment of the wire, we decided to propose our model of induction preheater, called CLIP-H (acronym of Contact Less Induction Pre-Heater).

The main features of the CLIP-H preheater

ELECTRICAL CHARACTERISTICS

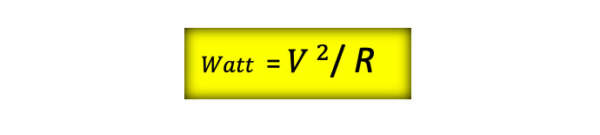

Power Section

– J-DRIVE static power converter

– Power supply 2 x 400V-50/60Hz

– Disconnector with door lock

– Power 15 kW

– Current 37/45Amp

– Adjustable overload limitation

– Voltage accuracy < 0.1%

– Extra rapid current protection

– Galvanic isolation Power/Control

– Digital line speed transducer

– Internal ventilation with filters

– Access Door Security Module

Sezione Software

– Siemens S7-1200 controller

– Profinet interface

– Operating Modes: Constant voltage – Variable voltage

– Generation of Quadratic Curve Families

– Manual mode tracing preheating curves

– Digital line speed acquisition

– Galvanic isolation Power/Control

MECHANICAL CHARACTERISTICS

Structure

– Tubular steel supports

– Lateral lifting eyebolts

– Swivel castors with a parking brake

– Drag handles

– Total height mm 1308

– Pass line mm 1045

– Width mm 400

– Adjustable base supports L= mm 573 – 453

– Total depth mm 705

– Ceramic wire inlet-outlet bushings

– Plexiglass side guards

– Front door with transparency screen printing

– Electric lock

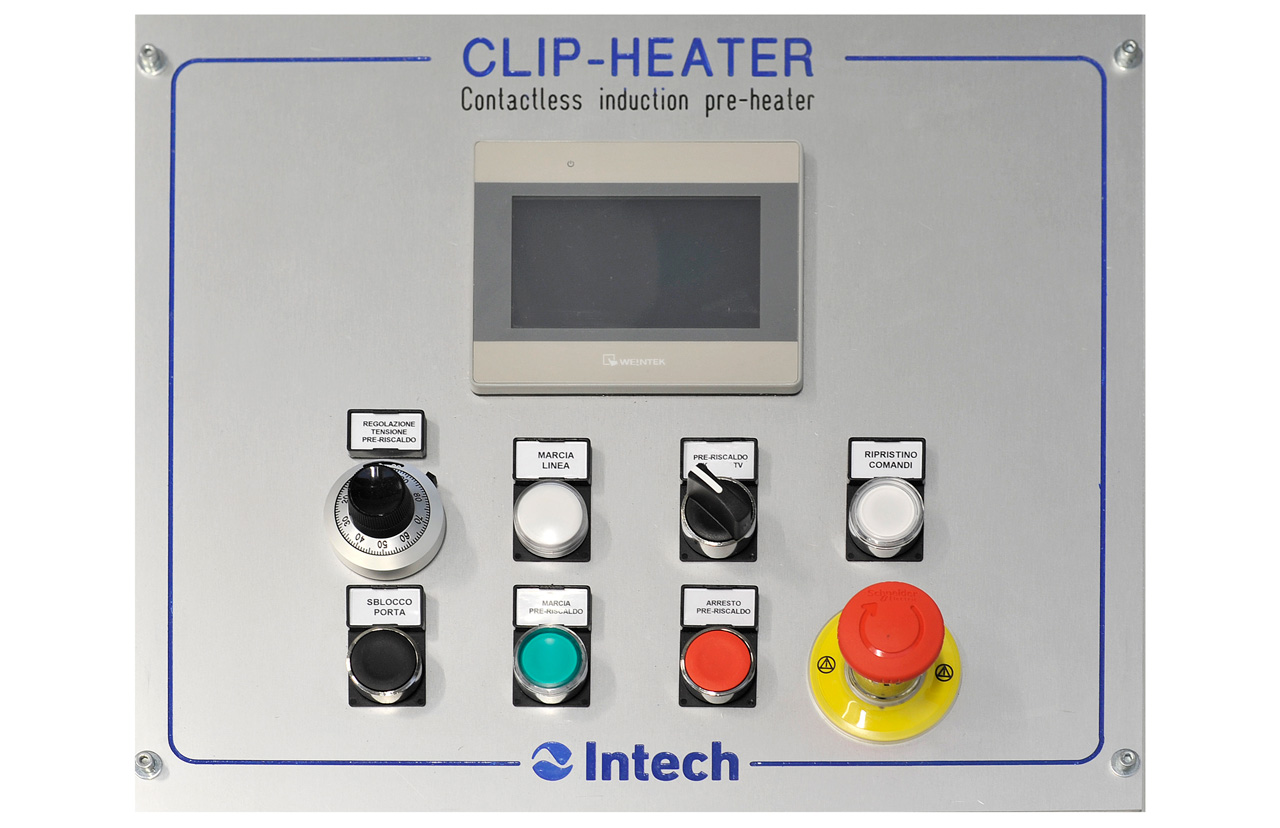

Quadro Elettrico

– Dimensions mm 600 x 400 x 200

– Command desk mm 155 x 495 x 60 inclined 11°

– Cable entry from below

– Cable entry protection removable ½ threaded knobs

Pulpit operator

4” T.S. HMI colour operator interface for LECTERN PANEL:

– Preheating curve tracing

– Setting recipes

– Line speed setting

– Setting wire section

– Line speed display

– Primary transformer voltage display

– J-Drive output current display

– Fault display

–

Commands

– Illuminated switch-on/reset button

– Running line warning lamp

– Potentiometer Tracking Preheating Curves

– Constant voltage/Variable voltage mode selector

– Start-Stop buttons CLIP-H

– Door release button

– CLIP-H Emergency Mushroom (Function extended to Emergency Line: optional with activation from HMI)

Future developments

There is ongoing research and investigation into non-contact temperature sensing devices, e.g. cameras and infrared transducers, for small diameter wires (<5mm),

The aim is to realise, in addition to the temperature display, complete closed-loop control of the temperature from the PLC with feedback directly from the sensor.

The open-loop control system will, of course, be maintained, as in the current units, in the event of a temperature detector failure.

In case of special customer requests, we are able to develop and modify CLIP-H to adapt it to any need by developing custom solutions.